Business Need

Mathesis Labs to develop a predictive analytics solution for predicting equipment (fixed & mobile equipment) failure in ball mill gearboxes.

Business Benefits

Solution Highlights

Data Analysis Inputs:

- Analyzed mill-related data, data sheets, system overviews, drawings, photos, FMEA reports, and O & M Manuals.

- Utilized standard task procedures, including alignment, etc.

Condition Monitoring:

- Analyzed MHM analysis reports & history, lube analysis reports, and external condition monitoring reports.

- Incorporated process and condition monitoring data from OSIPI and SAP-PM history.

Failure History Identification:

Identified failure history, including chipped gear tooth, gear & pinion bearing failures, pipe resonance, etc.

Data Normalization:

Normalized 157 parameters spread across separate flat files for efficient analysis.

Data Analysis Approach:

Applied slice and dice techniques while analyzing failures with contextual links to the condition data across all shared reports.

Root Cause Analysis:

- Utilized Cause & Effect Diagram for comprehensive root cause analysis.

- Conducted engineering analysis of gear & pinion failures, considering factors such as vibration, lubrication, misalignment, etc.

Failure Mode Effects & Criticality Analysis (FMECA):

Identified predictor variables and performed FMECA to enhance understanding of failure modes.

Fatigue Propagation Techniques:

Applied fatigue propagation techniques at the system level, considering root cause, sub-system degradation, and failure propagation.

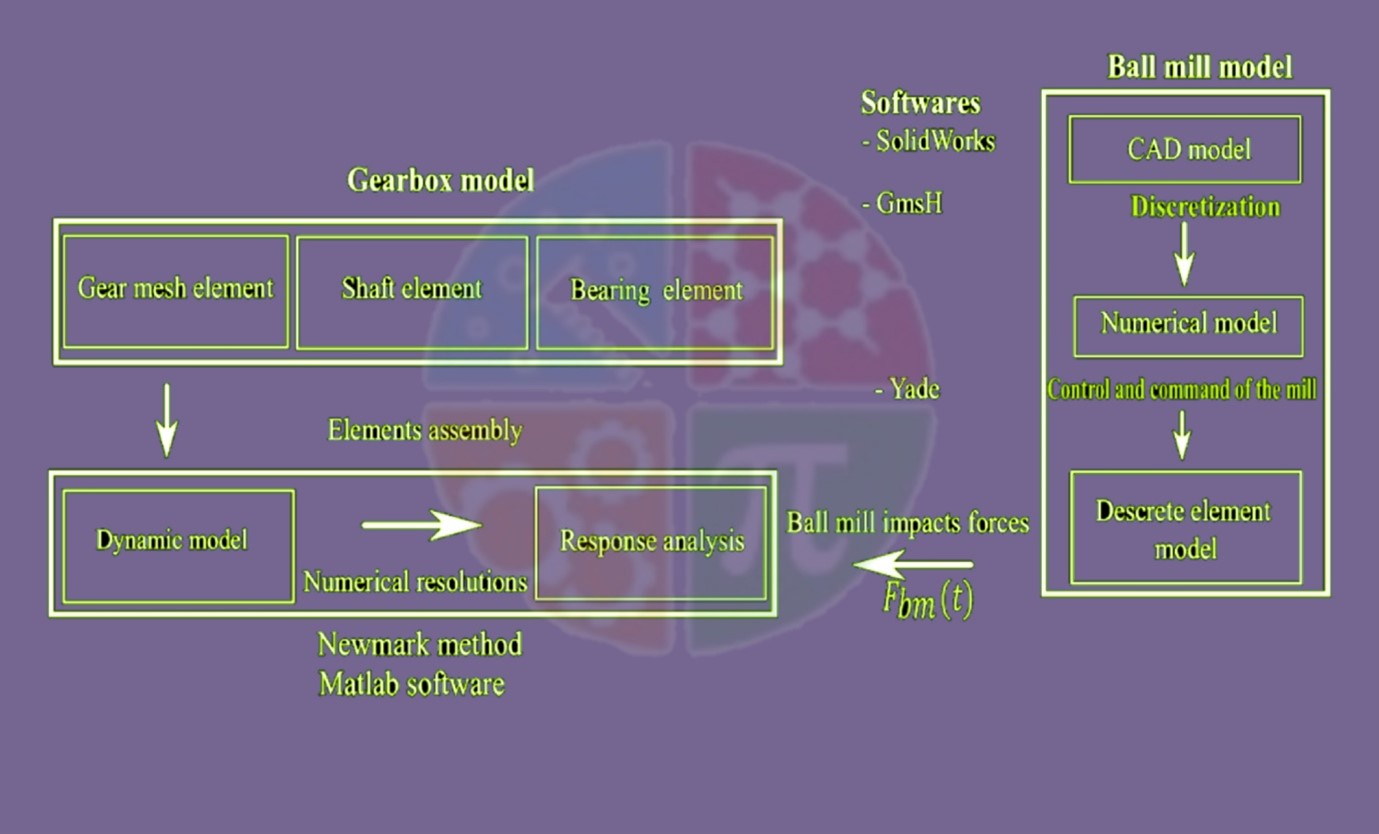

Prediction Model Building:

Built a robust prediction model to predict gearbox failure based on analyzed data.

Benefits

Life Prediction and Health Index:

Provided life prediction of the gearbox and machine health degradation indexes for proactive maintenance.

Cost Savings:

Achieved over 20% savings on maintenance costs through predictive maintenance strategies.

The Results

Mathesis Labs’ predictive analytics solution revolutionizes ball mill gearbox maintenance, offering a data-driven approach to equipment health management. The comprehensive analysis, root cause identification, and predictive modelling contribute to substantial cost savings and improved operational efficiency.