Digital Transformation = Digital Thread & Digital Twin

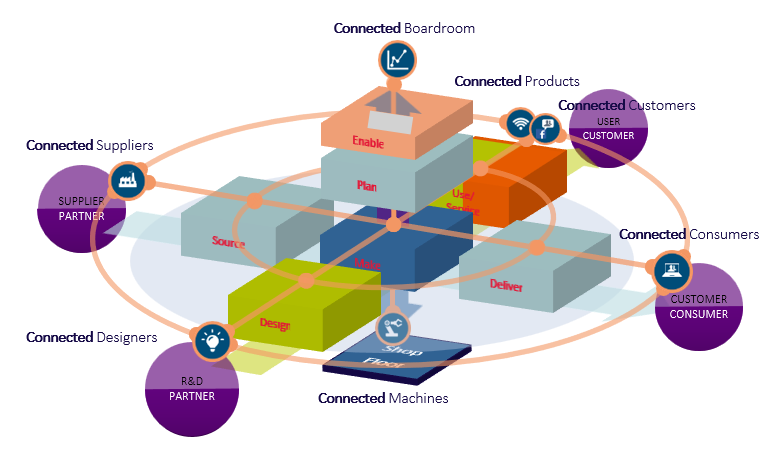

Intelligent Phygital for Manufacturing

Connectivity to the outside world

- Consumers providing direct feedback to product designers

- Products providing online customer/product profile data

- Individually customized products & services

- Smart Products generating usage data

- Suppliers becoming Co-designers

- Customers directly influencing product design

Connectivity within the Enterprise

- Vertical integration

- Horizontal integration

Experience – Vertical & Solutions

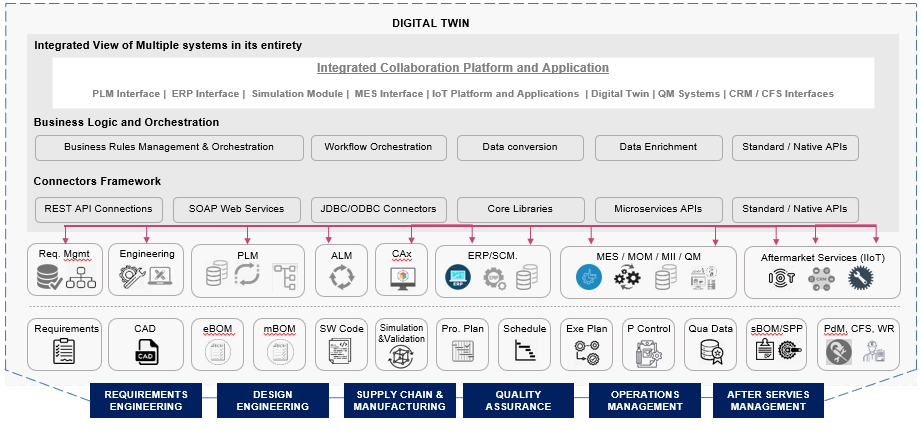

Engineering, IT to DT – Reference Architecture

- Discrete Industry Digital Twins: Used in the discrete industries where OEMs manage the PLM value stream including as-designed, as-built, as-serviced, and servitization. Also, digital twins for assembly line design and commissioning shorten the time to production with reduced risk

- Process Industry Digital Twins: Applied to plants for information and business process management during:

- Design and build project for a plant across potentially thousands of engineering and contractor personnel for engineering, procurement, and construction (EPC)

- Operations and maintenance phase of a plant’s lifecycle across the asset management functions that are often departmental silos

- Building Information Modeling involves design and construction of commercial buildings. After handover, this type of twin can extend into operations for building management including new tenant buildouts, upgrades, office occupancy optimization, HVAC energy management, and security.

- Infrastructure Digital Twins are used in the design and build of architecture, engineering, and construction (AEC) projects including highways, bridges, airports, dams, utilities (power, telecommunications, and water), and a variety of other major infrastructure.

- City Digital Twins provide a platform for city planning and management including zoning, vehicle and pedestrian traffic, disaster response, utilities, infrastructure, hydraulic modeling, and carbon emissions.